Single Screw Lab Extruder

It is suitable for making the Non-Puff product.

1. Product: Pasta macaroni,Dog Chews,Fried Pellets

2. Capacity: 100kg/hour,150kg/hour, 300kg/hour

3. Screw material: 38CrMoAl and CrMo12V Alloy steel

Product Features:

1. Automatic temperature control system

2. Automatic raw material feeding system

3. Extrusion system is made by Single screw with the main motor and gear box.The screw is alloy steel. The speed of the Motor is controlled by Inverter.

4. The cutting system is made by the cutting blade and Cutting motor. The cutting speed is controlled by Inverter

5. For Pasta making there is important system “Vacuum system” for producing quality pasta

Single Screw Lab Extruder Video

Single Screw Lab Extruder Features:

1. Computerized temperature control system

2. Automatic uncooked fabric feeding gadget

3. Extrusion machine is made via unmarried screw with the main motor and gear box.the screw is alloy steel. the rate of the motor is controlled by way of inverter.

4. The reducing machine is made by the reducing blade and cutting motor. the reducing speed is controlled by inverter

5. For pasta making there is vital machine “vacuum system” for generating excellent pasta

Dog Chews made by Single-Screw Extruder

Pasta macaroni made by Single screw Extruder:

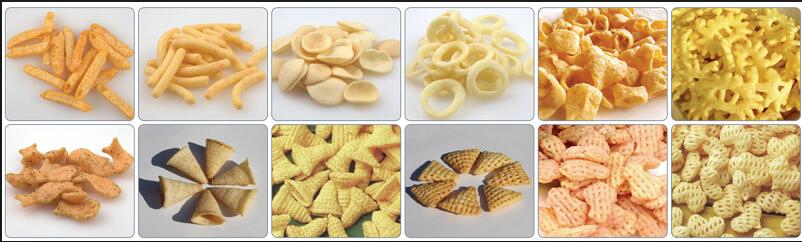

Fried Pellets snack made by single screw extruder:

Single Screw Lab Extruder Parameters:

No. | Item | Details |

1 | Engine power | 5.5KW |

2 | Dimension | 2200mm×800mm×1600mm |

3 | Engine speed-control | Frequency speed-control |

4 | Screw diameter | ∮30mm |

5 | Screw central distance | 26mm |

6 | Speed range | 0-500rpm |

7 | Screw mode | Building block-combined type |

8 | L/D | 36.6 |

9 | Material of screw | 38CrMoAl nitriding treatment |

10 | Heating way | Electricity Heating |

11 | Cylinder type | Divided cylinder (5 SECTIONS) |

12 | Cylinder cooled | Water Cooling |

13 | Temperature scope | 20℃-300℃ |

14 | Temperature precision | ±1.0℃ |

15 | Number of measuring temperature point | 5 points |

16 | Output | 5-15KG/H |

17 | Material of cover | SUS 304 |

18 | Pressure scope | 0-30MPa |

19 | Pressure precision | 0.1MPa |

20 | Number of measuring pressure point | 1 point |

21 | Number of degassing | 2 point (One free, the other forced) |

22 | Number of raw material feeding point | 3 |

23 | Number of water feeding point | 3 |

24 | Motor Brand | Siemens |

25 | Control system | PLC,Touch screen control |

Whatsapp:86 18406585795

Ms. Vivian

Related Products

Related News

Submitted successfully

We will contact you as soon as possible