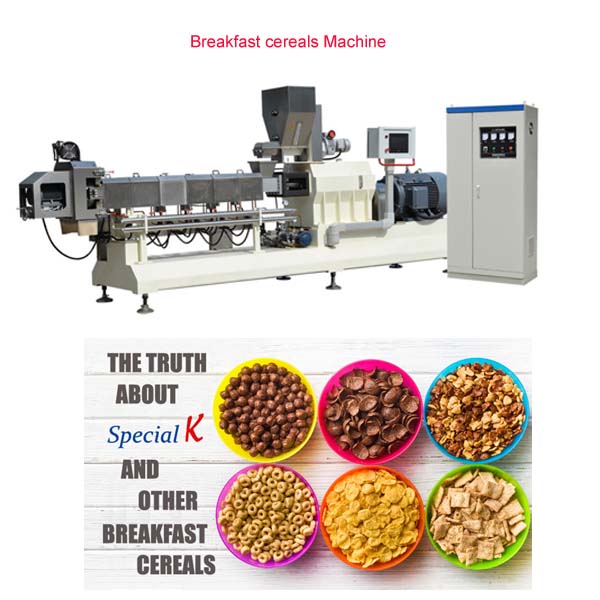

Breakfast Cereal processing line

The breakfast cereal processing line is a series of machinery and equipment used to produce various types of breakfast cereals such as cornflakes, wheat flakes, oat flakes, and rice crisps. The process typically involves mixing grains and other ingredients, cooking them to form a paste, shaping the paste into flakes or puffs, toasting or drying them, and adding flavorings and coatings. The processing line usually consists of a mixer, extruder, dryer, coater, and packaging machinery. The mixer is used to combine the grains and other ingredients, while the extruder shapes the mixture into the desired cereal shapes. The dryer removes moisture from the cereal to ensure crispy texture. The coater adds flavorings, vitamins, or coatings to enhance the taste and appearance of the cereal. Finally, the packaging machinery packages the cereal into boxes or bags for distribution. Overall, the breakfast cereal processing line is essential for the efficient and consistent production of breakfast cereals on a large scale. It allows manufacturers to create a variety of cereal products to meet consumer demands for tasty and nutritious breakfast options.

Breakfast cereal processing line video:

Breakfast cereal processing line description:

The breakfast cereal processing line is a complete set of equipment used to produce various types of breakfast cereals, such as corn flakes, rice crisps, and oat clusters. The processing line consists of different machines that perform specific functions, such as mixing, extrusion, drying, coating, and packaging. The process starts with mixing ingredients like grains, sugar, flavorings, and vitamins in the mixing machine. The mixed dough is then fed into an extruder, where it is shaped into various shapes like flakes or loops. The extruded cereal is then dried in an oven to remove moisture and create a crispy texture. After drying, the cereal may undergo a coating process to add flavors or protective coatings. Finally, the finished cereal is packaged into bags or boxes for distribution to consumers. Breakfast cereal processing lines are highly automated and can produce large quantities of cereal in a fast and efficient manner. They are commonly used by food manufacturers to produce a variety of popular breakfast cereal brands.

Breakfast cereal processing line parameter:

Model | Install Power | Real Power | Capacity | Dimension |

SLG65 | 105KW | 70KW | 150kg/h | 25x 2.0 x 3.0 |

SLG70 | 160KW | 112KW | 250kg/h | 27x 2.0 x 3.0 |

SLG85 | 210KW | 150KW | 500kg/h | 35x 2.0 x 3.0 |

Please contact us for the Breakfast Cereals Processing Machine Quotation:

WhatsApp:+86 186 6898 8231

Mr.Fred (Director)

Related Products

Related News

Submitted successfully

We will contact you as soon as possible