Core Filled Snack Food Machine

The Core Filled Snack Food Machine is an advanced and integrated production system designed for the efficient and automated manufacturing of a wide variety of core-filled snacks, such as filled biscuits, pastries, or extruded snacks. With its advanced automation features, the machine line significantly reduces labor costs and minimizes human error, ensuring consistent product quality and high output rates.

Video of Core Filled Snack Food Machine:

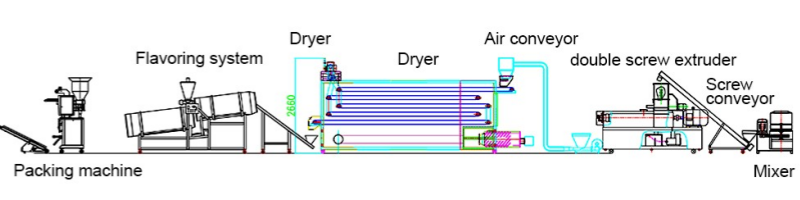

Core Filled Snack Food Machine:

The core filled snack food machine line is highly customizable to meet specific product requirements and production scales. It is designed for efficiency, hygiene, and minimal waste, making it an essential solution for modern snack food manufacturers. The core-filled snack food machine line is an advanced and integrated production system designed for the efficient and automated manufacturing of a wide variety of core-filled snacks, such as filled biscuits, pastries, or extruded snacks. This line typically includes several key components that work seamlessly together to ensure high-quality output and consistent production.

Process of core filled snack food machine:

1. Mixing raw material:

The process begins with a mixer that blends raw ingredients. The mixer ensures evenly mixing with blades inside.

2. Extruding raw material into shape:

The dough is then fed into twin screw extruder, which cooks and shapes it into the desired size and shape (e.g., sheets, tubes, or individual pieces).

3. Core Filling Injection:

A specialized filling machine accurately injects the core filling (e.g., chocolate, jam, cream, or cheese) into the products. This step ensures even distribution and precise filling amounts.

4. Drying products:

The filled products is conveyed to dryer. Temperature and time are carefully controlled through controller.

5. Coating:

The flavoring roller, sugar melting machine and sugar spraying machine will spray the sugar or other liquid on the surface of products for better tastes.

6.Cooling:

After baking or cooking, the snacks move through a cooling conveyor to stabilize their structure and prepare them for packaging.

7. Packaging:

Finally, the snacks are packaged using automated packaging machines, which can include options like flow wrapping, bagging, or box filling. Packaging ensures product freshness and extends shelf life.

The core-filled snack food machine line is highly customizable to meet specific product requirements and production scales. It is designed for efficiency, hygiene, and minimal waste, making it an essential solution for modern snack food manufacturers.

Core Filled Snack Food Machine Parameter:

Model | Install Power | Real Power | Capacity | Dimension(M) | Workshop size (㎡) |

SLG65 | 70KW | 50KW | 120-150kg/h | 20x 2.0 x 3.0 | 100 |

SLG70 | 110KW | 80KW | 220-250kg/h | 25x 2.0 x 3.0 | 120 |

SLG85 | 180KW | 140KW | 450-500kg/h | 32x 2.0 x 4.0 | 150 |

Sample:

Whatsapp: 86 18406585795

Ms. Vivian

Related Products

Related News

Submitted successfully

We will contact you as soon as possible