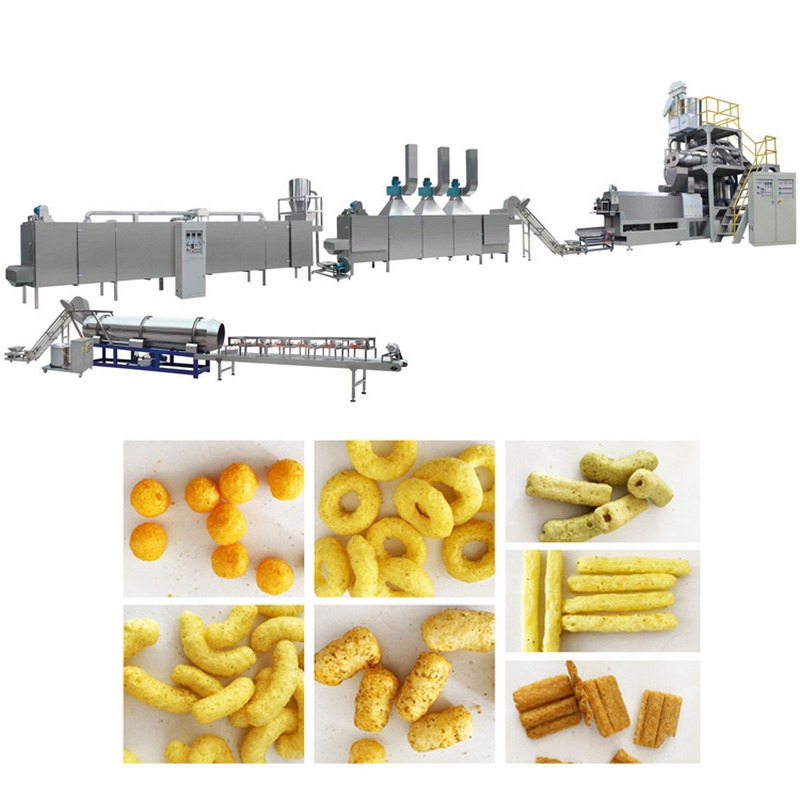

Puff Snack Extruder Processing Line

Puff Snack Extruder Processing Line is a highly efficient and automated production system designed for manufacturing a variety of puffed snack foods, such as cheese puffs, corn curls, and other extruded snacks. This production line integrates advanced technology and precision engineering to ensure consistent quality, high output, and versatility in snack production.

Puff Snack Extruder Processing Line Video:

Puff Snack Extruder Processing Line Introduction:

Jinan Saibainuo Machinery Co.,Ltd a leading manufacturer in the food processing machinery industry, is proud to announce the launch of its state-of-the-art Puff Snack Food Machine Line. Designed to meet the growing demand for high-quality, efficient, and versatile snack production, this cutting-edge machinery is set to transform the way puff snacks are manufactured. The new Puff Snack Food Machine Line boasts unparalleled efficiency, capable of producing a wide variety of puff snacks, including cheese puffs, corn curls, and ball shapes. With its advanced automation features, the machine line significantly reduces labor costs and minimizes human error, ensuring consistent product quality and high output rates.

Puff Snack Extruder Processing Line Parameter:

The Puff Snack Extruder Processing Line have some kind of models for customers to choose.

Model | Install Power | Real Power | Capacity | Dimension(M) | Size of workshop(㎡) |

SLG65 | 70KW | 50KW | 120-150kg/h | 20x 2.0 x 3.0 | 100 |

SLG70 | 110KW | 80KW | 220-250kg/h | 25x 2.0 x 3.0 | 120 |

SLG85 | 180KW | 140KW | 450-500kg/h | 32x 2.0 x 4.0 | 150 |

Product Sample:

Product Features:

The main raw material is Corn flour, rice flour, wheat flour, sugar and oil

From the raw material to the final product packed in bags the whole process is automatically.

1. Machines are High automatically (just need 2-3 operators)

2. Machine temperature and speed is automatic control

3. It produce the Corn puff snacks and Core filling snacks

4. The Puff snack food machine is PLC control, touch screen operate

5. Big output (From 100kg/hour to 500kg/hour)

Product Advantages:

1. High Production Capacity: Designed for mass production, meeting the demands of large-scale snack manufacturers.

2. Consistent Quality: Precise control over each stage of the process ensures uniform product quality.

3. Cost-Effective: Automation and energy efficiency reduce operational costs.

4. Customizable: Can be tailored to produce unique snack shapes and flavors based on market trends.

5. Durability: Built with high-quality materials for long-lasting performance and minimal downtime.

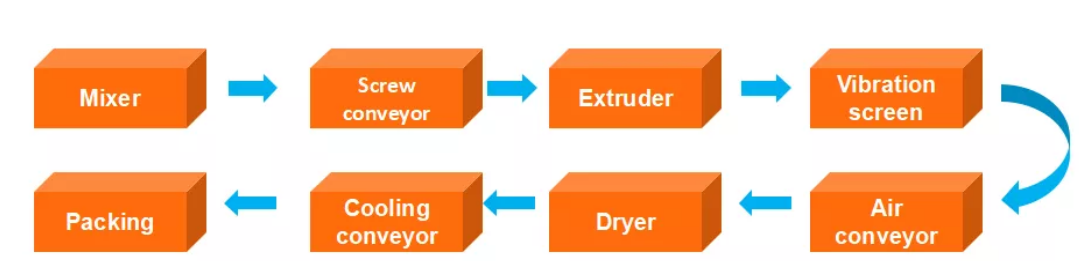

Product process:

Services:

Before Sales:

1. We provide the layout design according to customer workshop dimension

2. We provide the formulation of the fish feed

3. We provide the cost analysis to help customer check their market

4. We trail ran fish feed machine in our factory for customers before shipment

5. We provide the specification of machines

After-sales Service

1. Engineer to customers’ factory to install the machine

2. Engineers train the customers operation and maintenance

3. Develop the formulation to customers

4. Help customer to upgrade their machine in the future

5. Guide the customers by Email and Call

6. Provide the good quality low cost spare parts to customers.

Whatsapp: 86 18406585795

Ms. Vivian

Related Products

Related News

Submitted successfully

We will contact you as soon as possible