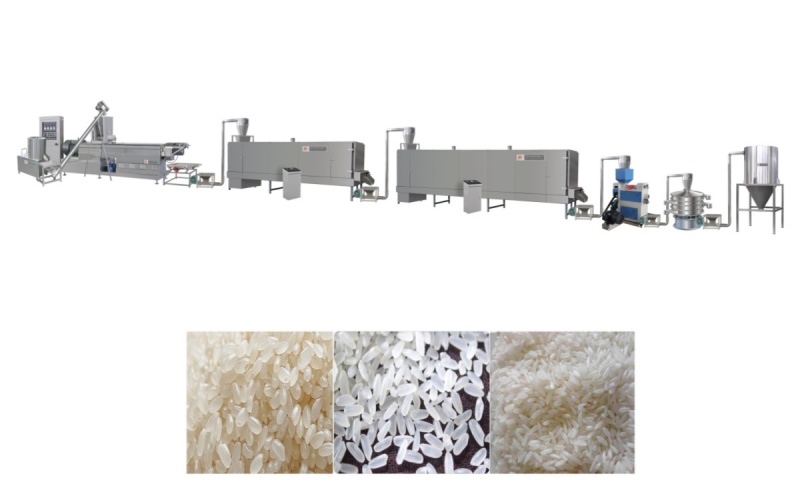

Artificial Rice Extruder Machine Line

Why Choose This Artificial Rice Extruder Machine Line?

✔ Nutrient Retention – Advanced extrusion and drying minimize vitamin loss.

✔ High Capacity – Output ranges from 200-800kg/h, scalable for large projects.

✔ Customizable Fortification – Adjust micronutrient blends for regional dietary needs.

✔ Minimal Waste – Closed-loop system recycles excess material, improving efficiency.

✔ Easy Maintenance – Stainless steel construction meets food-grade (ISO/CE) standards.

Artificial Rice Extruder Machine Line Video:

Artificial Rice Extruder Machine Line Introduction:

This fully automated production line transforms rice flour into nutrient-enriched fortified rice, designed to combat malnutrition while maintaining the appearance, texture, and taste of natural rice. The process ensures precision, scalability, and superior product quality—making it ideal for large-scale nutrition programs and commercial food manufacturing.

Artificial Rice Extruder Machine Line Parameter:

There are several models for customer to choose:

Model | Install Power | Real Power | Capacity | Dimension |

SLG70 | 110KW | 77KW | 180-200kg/hour | 22x 2.0 x 3.0 |

DLG100 | 105KW | 73KW | 150-180kg/hour | 22x 2.0 x 3.0 |

DLG150 | 190KW | 135KW | 300-350kg/hour | 30x 2.0 x 3.0 |

DLG150-II | 300KW | 210KW | 600-700kg/hour | 40x 3.5 x 4.0 |

Machine process:

Mixing (Mixer): Rice flour is blended with water and nutrient premix (vitamins, minerals, etc.) in a high-speed mixer.

Extrusion (Extruder): The moist mixture is fed into a twin-screw extruder, where it undergoes cooking, gelatinization, and puffing under high temperature and pressure. The extruded raw material is shaped into rice-like grains using a mold (die) to mimic natural rice kernels.

Drying (Dryer): The extruded rice passes through a multi-stage dryer to reduce moisture content (typically to ~12%), ensuring shelf stability and hardness. Hot air circulation ensures uniform drying without cracking.

Cooling (Cooling Conveyor): The dried rice is transported on a cooling conveyor to ambient temperature, preventing condensation during packaging. Enhances texture and prevents clumping.

Whatsapp:86 18406585795

Ms. Vivian

Related Products

Related News

Submitted successfully

We will contact you as soon as possible