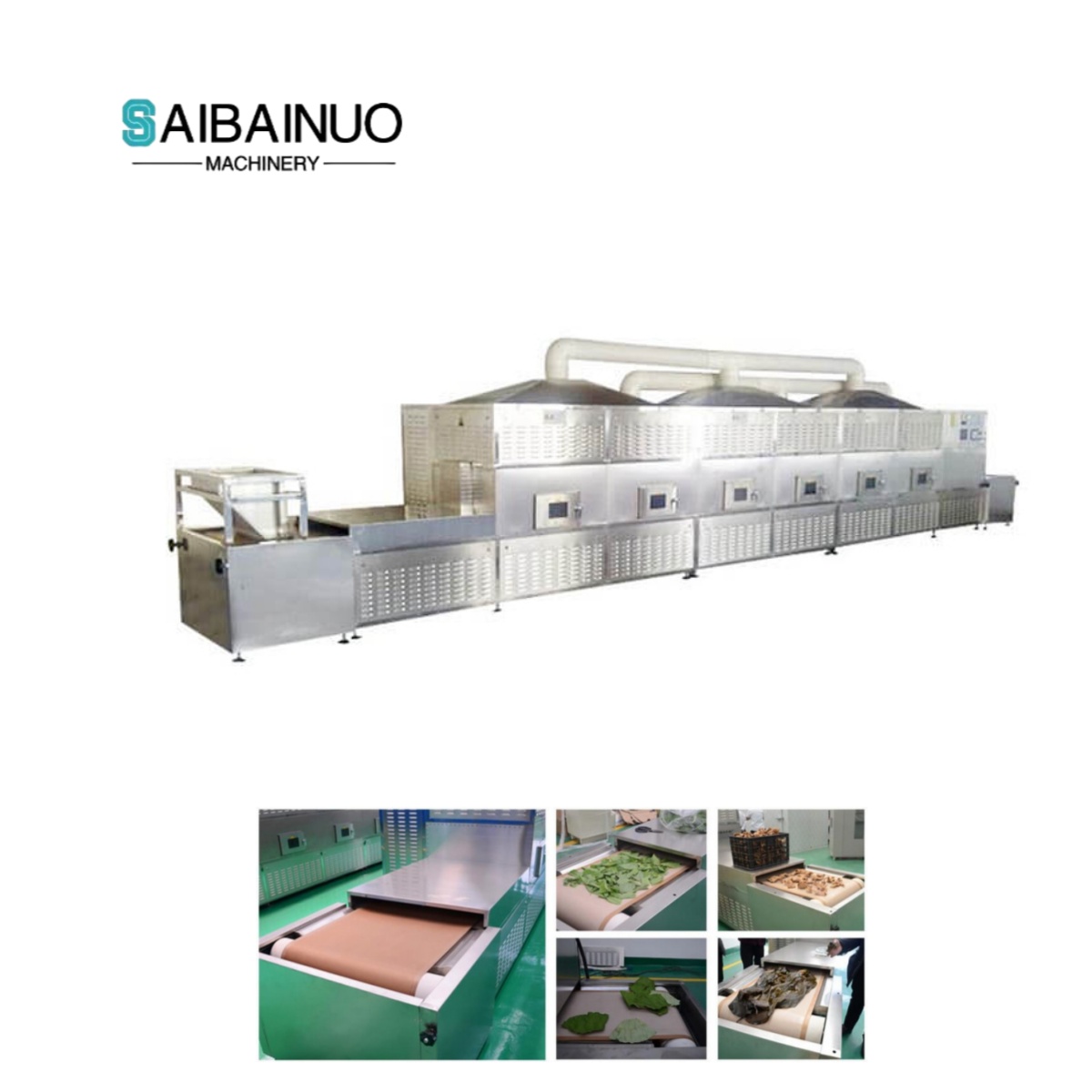

Industrial Microwave Oven Machine

This Industrial Microwave Oven Machine can be controlled easily. So it can be used to dry the food continuously to save labor.So higher thermal efficiency and more energy saving, which is heating energy-saving1/3 over than the far infrared heating.

Industrial Microwave Oven Machine Video:

Heating method: Microwave

Heating power: 10kw-300kw

Electric parts brand: SIEMENS

Machine material:SUS304

Function: Dry Vegetable, snacks, grains,wood, powder

Industrial Microwave Oven Machine Specification:

Microwave directly effects on water molecules, heating materials from inside to outside at the same time, without power loss, no waste water, waste gas, waste residue or other pollution discharge during microwave work. Compared with the traditional drying method, microwave dryer has the advantages of high heating efficiency, evenly drying, energy saving features, etc

Microwave Drying Machine photo:

Industrial Microwave Oven Machine Parameters:

NO. | Modle | Power | Dehydration capacity(kg/h) | sterilization capacity(kg/h) | Size L*W*H(mm) |

1 | SBN-12KW | 12KW | 12kg/h | 120-150kg/h | 7000mm*840mm*1750mm |

2 | SBN-20KW | 20KW | 20kg/h | 190-240kg/h | 9400mm*840mm*1750mm |

3 | SBN-30KW | 30KW | 30kg/h | 300-375kg/h | 11700mm*840mm*1750mm |

4 | SBN-40KW | 40KW | 40kg/h | 400-500kg/h | 10500mm*1060mm*1750mm |

5 | SBN-50KW | 50KW | 50kg/h | 500-625kg/h | 11700mm*1060mm*1750mm |

6 | SBN-60KW | 60KW | 60kg/h | 600-750kg/h | 13000mm*1060mm*1750mm |

7 | SBN-70KW | 70KW | 70kg/h | 700-875kg/h | 14000mm*1060mm*1750mm |

8 | SBN-80KW | 80KW | 80kg/h | 800-1000kg/h | 12860mm*1200mm*1750mm |

9 | SBN-100KW | 100KW | 100kg/h | 1000-1250kg/h | 15000mm*1200mm*1750mm |

10 | SBN-150KW | 150KW | 150kg/h | 1500-1875kg/h | 21000mm*1200mm*1750mm |

microwave Frequency:2450±50MHz | |||||

Transmission speed:0-10m/min(adjustable) | |||||

microwave leak:<1 mw/cm^2) | |||||

Cooling way: Oil,water and wind cooling | |||||

Before Sales:

1. We provide the drawing design according to customer workshop

2. We provide the formulation

3. We provide the cost analysis

4. We trail ran Pet Food Machine for customers

5. We provide the specification of machines

After-sales Service

1. Engineer to customers’ factory to install the machine

2. Engineers train the customers operation and maintenance

3. Develop the formulation to customers

4. Provide the upgrade on machines

5. Guide the customers by Email and Call

6. Provide the good quality low cost spare parts to customers.

Whatsapp: 86 18406585795

Ms. Vivian

Related Products

Related News

Submitted successfully

We will contact you as soon as possible