Nik Naks Making Machine Line

*High Efficiency: Capable of producing large quantities of snacks in a short time.

*Customization: Flexible to produce various shapes, sizes, and flavors.

*Hygiene and Safety: Designed with food-grade materials and easy-to-clean components.

*Energy Efficiency: Modern systems are optimized to reduce energy consumption and waste.

Nik Naks Making Machine Line Video:

Nik Naks Making Machine Line Introduction:

The Nik Naks Making Machine Line is a state-of-the-art solution for snack food manufacturers looking to scale production while maintaining high standards of quality and consistency.

*High Efficiency: Streamlined process flow ensures high production rates with minimal downtime.

*Customization: Flexible equipment allows for the production of various shapes, textures, and flavors.

*Consistency: Advanced controls ensure uniform product quality across batches.

*Sustainability: Energy-efficient design and reduced oil consumption contribute to lower operating costs and environmental impact.

*Ease of Maintenance: User-friendly design and durable materials simplify maintenance and extend equipment lifespan.

Nik Naks Making Machine Line Parameter:

Model | Install Power | Real Power | Capacity | Dimension | Area | Delivery |

DLG76 | 80KW | 55KW | 120kg/h | 20x 3.0 x 3.0 | 100m³ | 30 |

DLG76-II | 130KW | 90KW | 240kg/h | 28x 3.0 x 3.0 | 120m³ | 30 |

DLG76-III | 180KW | 120KW | 360kg/h | 35x 3.0 x 3.0 | 150m³ | 30 |

Machine Process:

1. Mixing

- Function: This part is responsible for mixing raw materials such as corn flour, rice flour, and water to make it even.

- Features: Equipped with high-speed mixers and stainless steel blades to make it even and mix it completely.

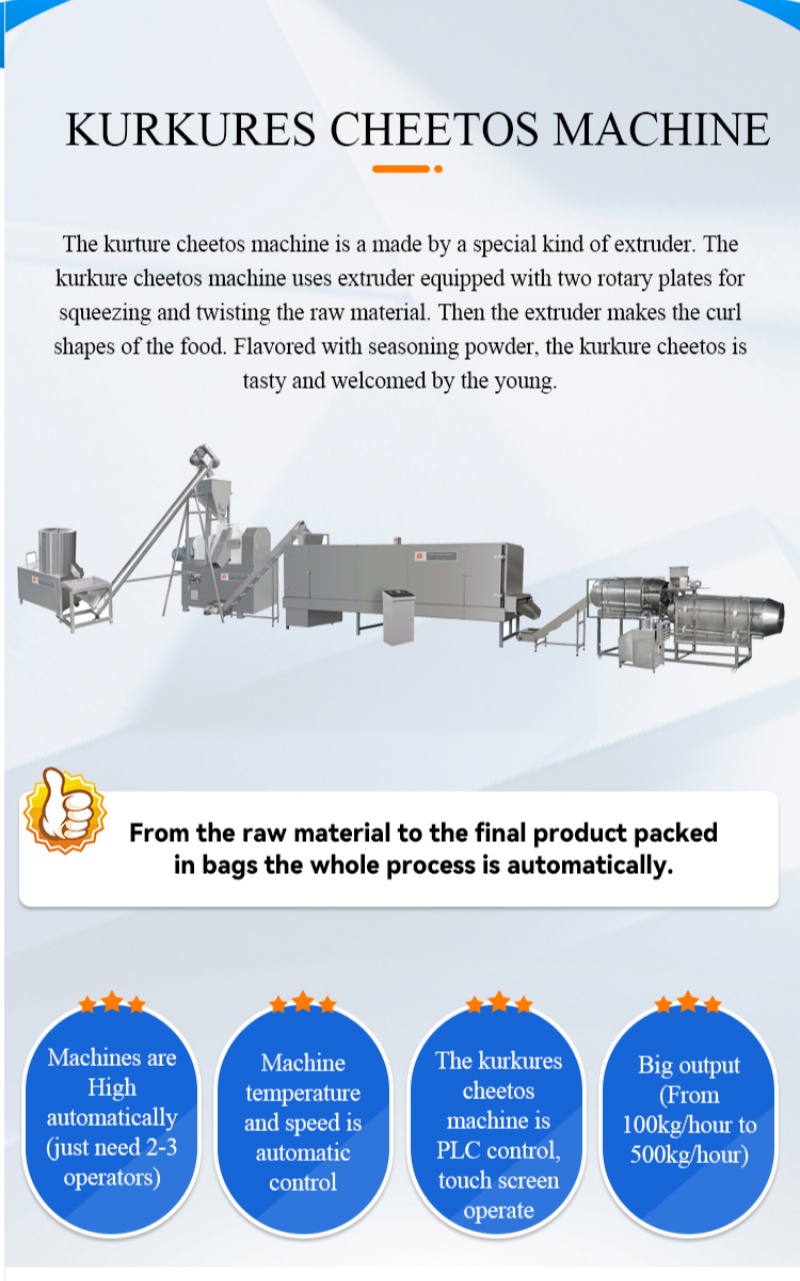

2. Extrusion

- Function: The mixed raw material is fed into an extruder, where it is cooked under high pressure and temperature, then shaped into the desired snack forms (e.g., curls, sticks, or balls).

- Features: Advanced extrusion technology allows for customizable shapes and textures. The machine can produce a variety of snack forms with minimal downtime.

3. Frying or Baking

- Function: The shaped snacks are either fried in hot oil or baked, depending on the desired product characteristics.

- Features: The frying unit uses temperature-controlled oil for consistent crispiness, while the baking option offers a healthier alternative with reduced oil content.

4. Seasoning and Flavoring

- Function: After frying or baking, the snacks are evenly coated with seasonings and flavors.

- Features: A rotating drum ensures uniform distribution of spices, cheese powder, or other flavorings.

5. Cooling

- Function: The snacks are cooled and dried to achieve the perfect texture and shelf stability.

- Features: Equipped with cooling conveyors and fans to remove excess moisture and heat.

Product Sample:

Whatsapp:86 18406585795

Ms. Vivian

Related Products

Related News

Submitted successfully

We will contact you as soon as possible