Nik Naks Processing Line

*High Efficiency: Streamlined process flow ensures high production rates with minimal downtime.

*Customization: Flexible equipment allows for the production of various shapes, textures, and flavors.

*Consistency: Advanced controls ensure uniform product quality across batches.

*Sustainability: Energy-efficient design and reduced oil consumption contribute to lower operating costs and environmental impact.

*Ease of Maintenance: User-friendly design and durable materials simplify maintenance and extend equipment lifespan.

Nik Naks Processing Line Video:

Nik Naks Processing Line Introduction:

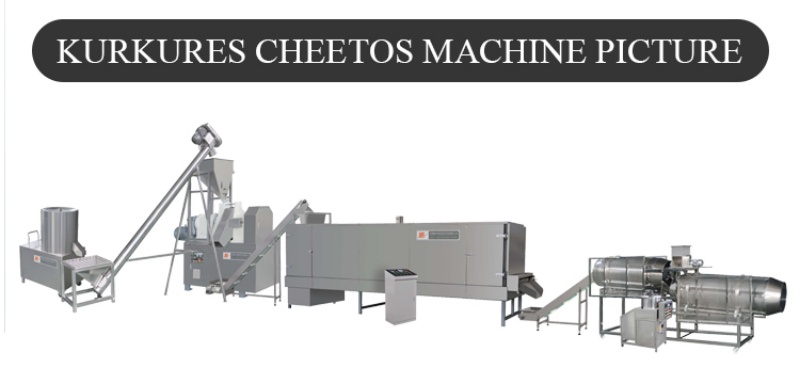

The Nik Naks Processing Line is a fully automated production system designed for the efficient and large-scale manufacturing of popular snack foods like Cheetos and Kurkures. This advanced machinery ensures consistent quality, high output, and minimal human intervention, making it ideal for snack food manufacturers.

Product Sample:

Nik Naks Processing Line Parameter:

Model | Install Power | Real Power | Capacity | Dimension | Area | Delivery |

DLG76 | 80KW | 55KW | 120kg/h | 20x 3.0 x 3.0 | 100m³ | 30 |

DLG76-II | 130KW | 90KW | 240kg/h | 28x 3.0 x 3.0 | 120m³ | 30 |

DLG76-III | 180KW | 120KW | 360kg/h | 35x 3.0 x 3.0 | 150m³ | 30 |

Machine Process:

1. Mixing

- Function: This part is responsible for mixing raw materials such as corn flour, rice flour, and water to make it even.

- Features: Equipped with high-speed mixers and stainless steel blades to make it even and mix it completely.

2. Extrusion

- Function: The mixed raw material is fed into an extruder, where it is cooked under high pressure and temperature, then shaped into the desired snack forms (e.g., curls, sticks, or balls).

- Features: Advanced extrusion technology allows for customizable shapes and textures. The machine can produce a variety of snack forms with minimal downtime.

3. Frying or Baking

- Function: The shaped snacks are either fried in hot oil or baked, depending on the desired product characteristics.

- Features: The frying unit uses temperature-controlled oil for consistent crispiness, while the baking option offers a healthier alternative with reduced oil content.

4. Seasoning and Flavoring

- Function: After frying or baking, the snacks are evenly coated with seasonings and flavors.

- Features: A rotating drum ensures uniform distribution of spices, cheese powder, or other flavorings.

5. Cooling

- Function: The snacks are cooled and dried to achieve the perfect texture and shelf stability.

- Features: Equipped with cooling conveyors and fans to remove excess moisture and heat.

Whatsapp:86 18406585795

Ms. Vivian

Related Products

Related News

Submitted successfully

We will contact you as soon as possible