Panko Bread Crumbs Extruder Machine

Bread crumbs are widely used in food additives, it was mainly added on the surface of fried food, such as fried steak, fried chicken, fried seafood, fried ring and other fried accessories. With adding the bread on the surface, these deep-fried foods will more crispy outside, and fresh taste inside.

Machine video:

Main raw material: Corn flour and wheat flour

Product: Bread crumb

Capacity:150kg/hour, 250kg/hour and 500kg/hour

Machine material: SUS304

Electric parts brand: SIEMENS

Product description:

This bread crumbs production line is ideal for producing high-quality, uniform bread crumbs at large scale. The use of the twin-screw extruder ensures precise control over the texture and quality of the final product, making it a popular choice in the food processing industry.

Bread crumb machine Photo:

Product features :

1. High Automation: The line is largely automated, meaning that much of the process, from mixing to drying, is controlled by machines. This reduces the need for manual labor and helps minimize human error, improving overall efficiency and consistency. Operators can easily control and monitor the system with user-friendly interfaces, making the process smooth and hassle-free.

2. Adjustable Production Parameters: The extruder’s temperature, pressure, and screw speed can be adjusted to control the texture of the bread crumbs (whether fine or coarse). This level of customization ensures flexibility in production for different market needs. The cutting machine offers adjustable settings for the size of the crumbs, allowing manufacturers to produce a wide range of bread crumbs, from very fine crumbs for breading to coarser crumbs for topping or snacks.

3. Continuous Production: The machine line is designed for continuous, high-capacity production, which is ideal for large-scale operations. The use of a twin-screw extruder and other efficient machinery ensures smooth operation without frequent interruptions, reducing downtime and increasing productivity.

4. Energy Efficiency: The design of the extruder and drying system focuses on energy efficiency, ensuring the line uses minimal electricity without compromising output. Modern heat recovery systems may be incorporated to further reduce energy consumption. The machines are designed to reduce waste and optimize resource usage, which helps in minimizing the environmental impact of the production process.

5. Stable Quality: The use of the twin-screw extruder ensures a highly uniform product, which is essential for maintaining consistent quality in bread crumbs. This helps to meet the exact specifications required for different food products and applications. The final bread crumbs are crispy, dry, and stable, with a long shelf life, making them suitable for packaging and distribution to various markets.

6. Hygienic Design: The machine line is built with food-grade stainless steel and designed for easy cleaning. This ensures a high level of hygiene, which is important in food processing to prevent contamination and maintain food safety standards. The design minimizes the risk of cross-contamination between batches, keeping the production process sanitary and compliant with food safety regulations

These additional features make the bread crumbs machine line not only highly efficient but also adaptable to different production needs, improving overall product quality, safety, and sustainability in the production process.

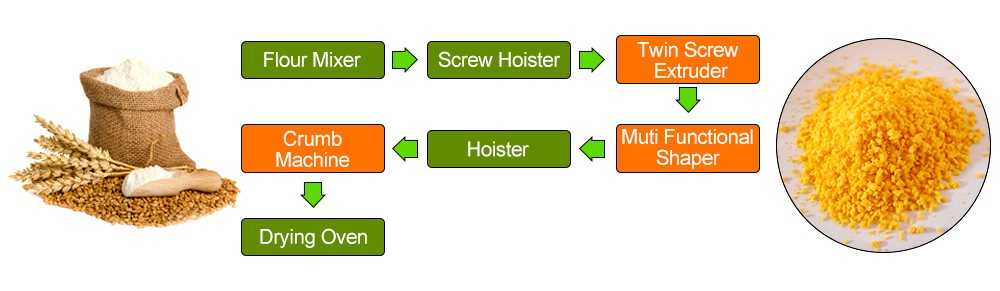

Bread crumb machine Flow Chart:

Bread crumb sample:

Here are some samples of products produced by bread crumb machine.

Product parameter:

There are three kind of capacity of bread crumb machine.

Model | Install Power | Real Power | Capacity | Dimension |

SLG65 | 80KW | 55KW | 140-150kg/h | 20x 2.0 x 3.0 |

SLG70 | 120KW | 85KW | 240-250kg/h | 25x 2.0 x 3.0 |

SLG85 | 180KW | 130KW | 450-500kg/h | 32x 2.0 x 5.0 |

Application:

The bread crumb machine produces bread crumb which can be used for food plant, supermarket, restaurant, snack plant.

Whatsapp:86 18406585795

Ms. Vivian

Related Products

Related News

Submitted successfully

We will contact you as soon as possible