Panko Bread Crumbs Machine Line

Panko Making Machine Manufacturers from raw materials, puffing, bran drying, dryer all in-line production, with fewer personnel, no waste, reducing manufacturing costs and improving labor productivity. The bread crumb is widely used as food coating additives on the surface of frying foods like: frying chicken, fish, sea foods (Shrimp), onion ring etc. The taste is fragrant, crispy, delicious and with rich nutrition.

Machine video:

Main raw material: Corn flour and wheat flour

Product: Bread crumb

Capacity:150kg/hour, 250kg/hour and 500kg/hour

Machine material: SUS304

Electric parts brand: SIEMENS

Product description:

A bread crumbs machine line that uses flour as the raw material and employs an extruder for production consists of several key pieces of equipment that work together to transform flour into bread crumbs. Bread crumb machine can produce various size of bread crumb food. The bread crumb is widely used in food additive, usually for fried food to make it crispy outside and soft inside. The bread crumb machine uses rice flour, corn flour and corn starch as raw material. Adopted with advanced technology, the bread crumb machine is highly automatic required easy operation for workers, thus it is welcomed by customers.

Bread crumb machine Photo:

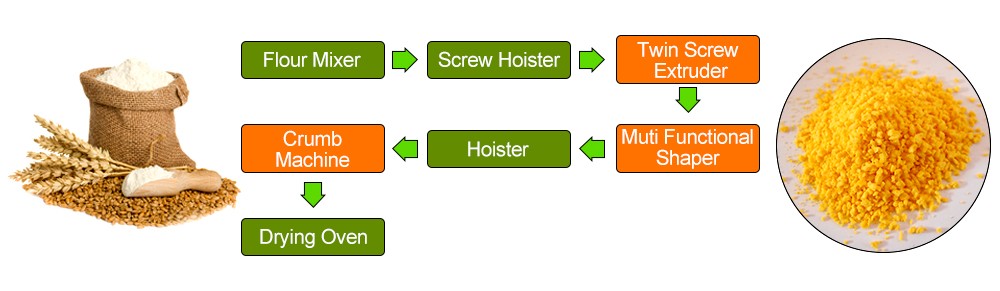

Flow Chart:

Bread crumb sample:

Here are some samples of products produced by bread crumb machine.

Product parameter:

There are three kind of capacity of bread crumb machine.

Model | Install Power | Real Power | Capacity | Dimension |

SLG65 | 80KW | 55KW | 140-150kg/h | 20x 2.0 x 3.0 |

SLG70 | 120KW | 85KW | 240-250kg/h | 25x 2.0 x 3.0 |

SLG85 | 180KW | 130KW | 450-500kg/h | 32x 2.0 x 5.0 |

Product features:

Here are some advantage of bread crumb machine.

*Advanced technology with high automation required easy operation.

*PLC banal can control each machine precisely and easily.

*The vibrating machine can filter different size of bread crumbs.

*The dryer has multiple layers for saving much space.

*Self cleaning without disassembling.

Process:

1. Mixer

Function: The first step in the production process is mixing the flour with water. The mixer ensures the evenly and completely mixing.

2. Twin Screw Extruder

Function: The mixed raw material is fed into a twin-screw extruder. This machine uses two interlocking screws to knead, cook, and shape the mixed raw material under controlled pressure and temperature. The extrusion process cook and shape the products.

Advantages: The twin-screw extruder is highly efficient, enabling high production capacity and consistency in the texture and quality of the bread crumbs. It also allows for flexible product customization based on customer requirements.

3. Cutting Machine

Function: After the material is extruded, the next step involves cutting the material into desired smaller size, which is convenient for crushing.

4. Crusher

Function: The cut pieces of products are then passed through a crusher to break down any larger pieces and ensure uniformity in size. The crusher helps in achieving the final, desired crumb texture, making sure the bread crumbs are evenly sized for further processing.

5. Dryer

Function: Once the bread crumb material has been shaped and crushed, it is passed through a dryer to remove excess moisture. The drying process is crucial to achieving the crispy, shelf-stable quality of the bread crumbs. Typically, a hot-air or tunnel dryer is used to ensure that the crumbs dry evenly and thoroughly, preventing any sogginess or spoilage.

6. Cooling Conveyors

Function: After drying, the bread crumbs are still hot and need to be cooled to room temperature. The cooling conveyors are used to gradually cool down the bread crumbs, ensuring they do not absorb moisture from the surrounding air and retain their crisp texture. This cooling process is important for maintaining product quality before packaging.

Application:

The bread crumb machine produces bread crumb which can be used for food plant, supermarket, restaurant, snack plant.

Services:

*Consultation service before, during,and after sales;

*Project planning and design service;

*Debugging of equipment until everything is functional;

*Management of equipment' long distance shipping from seller's factory to the named place by buyer;

*Training of equipment maintenance and operating personally;

*New production techniques and formulas;

*Provide 1 year complete warranty and life-time maintenance service.

Whatsapp: 86 18406585795

Ms. Vivian

Related Products

Related News

Submitted successfully

We will contact you as soon as possible