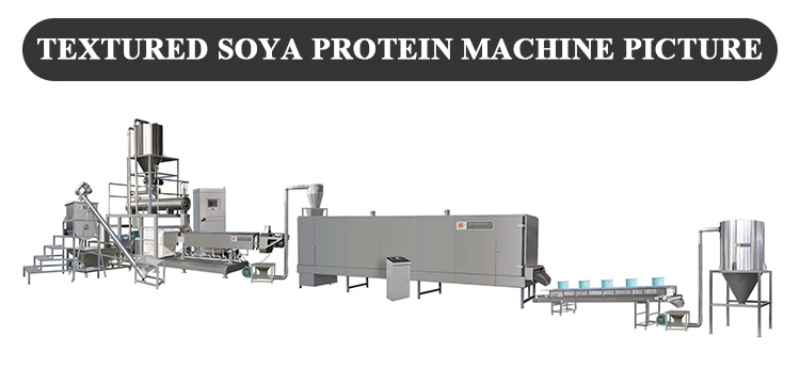

Soya Chunks Processing Line

This soy chunks processing line uses the soybean and the peanut as the raw material and makes the round protein moisture become the chain shape and reorganization then form the sheet fibre structure by grinding, mixing, conditioning, high temperature, high pressure and high cutting.

Soya Chunks Processing Line Video:

Main raw material: Defatted soy Meal, Soy protein,Wheat gluten

Product: Soy chunks

Capacity:260kg/hour, 600kg/hour and 1000kg/hour

Machine material: SUS304

Electric parts brand: SIEMENS

Soya Chunks Processing Line Description:

Soya Chunks Processing Line uses low temperature soy bean meal as main raw material to produce all kinds of textured protein food with high nutrition. As the textured soya protein is tasted like meat so it is welcomed by vegetarians. The textured soya protein machine is popular for many countries especially for developed countries who have more requirement for body health.

Soya Chunks Processing Line Sample:

Here are some samples of products produced by Soya Chunks Processing Line.

Soya Chunks Processing Line Parameter:

The parameter of Soya Chunks Processing Line.

Model | Install Power | Real Power | Capacity | Dimension |

SLG65-IV | 110KW | 77KW | 250kg/h | 20x 2.0 x 3.0 |

SLG65-V | 135KW | 95KW | 300kg/h | 25x 2.0 x 3.0 |

SLG85 | 210KW | 147KW | 600kg/h | 32x 2.0 x 4.0 |

SLG95 | 300KW | 200KW | 1200kg/h | 40x 2.0 x 5.0 |

Product Features:

✔ Modular design for scaling production capacity.

✔ Food-grade stainless steel construction for safety.

✔ PLC-controlled parameters (temperature, speed, moisture).

✔ Low waste with closed-loop water/energy systems.

Application:

The textured soya protein machine can produce high nutrition textured soya protein which can be widely used in food plant and restaurant.

Services:

Before Sales:

1. We provide the drawing design according to customer workshop

2. We provide the formulation

3. We provide the cost analysis

4. We trail ran Pet Food Machine for customers

5. We provide the specification of machines

After-sales Service

1. Engineer to customers’ factory to install the machine

2. Engineers train the customers operation and maintenance

3. Develop the formulation to customers

4. Provide the upgrade on machines

5. Guide the customers by Email and Call

6. Provide the good quality low cost spare parts to customers.

Whatsapp: 86 18406585795

Ms. Vivian

Related Products

Related News

Submitted successfully

We will contact you as soon as possible