Soya Minces Production Line

-Automated control system for precise adjustments in temperature, speed, and cutting.

-Energy-efficient drying and extrusion technology.

-Customizable for different textures (fibrous, spongy, or tender).

-Hygienic design with stainless steel contact parts.

Soya Minces Production Line Video:

Soya Minces Production Line Introduction:

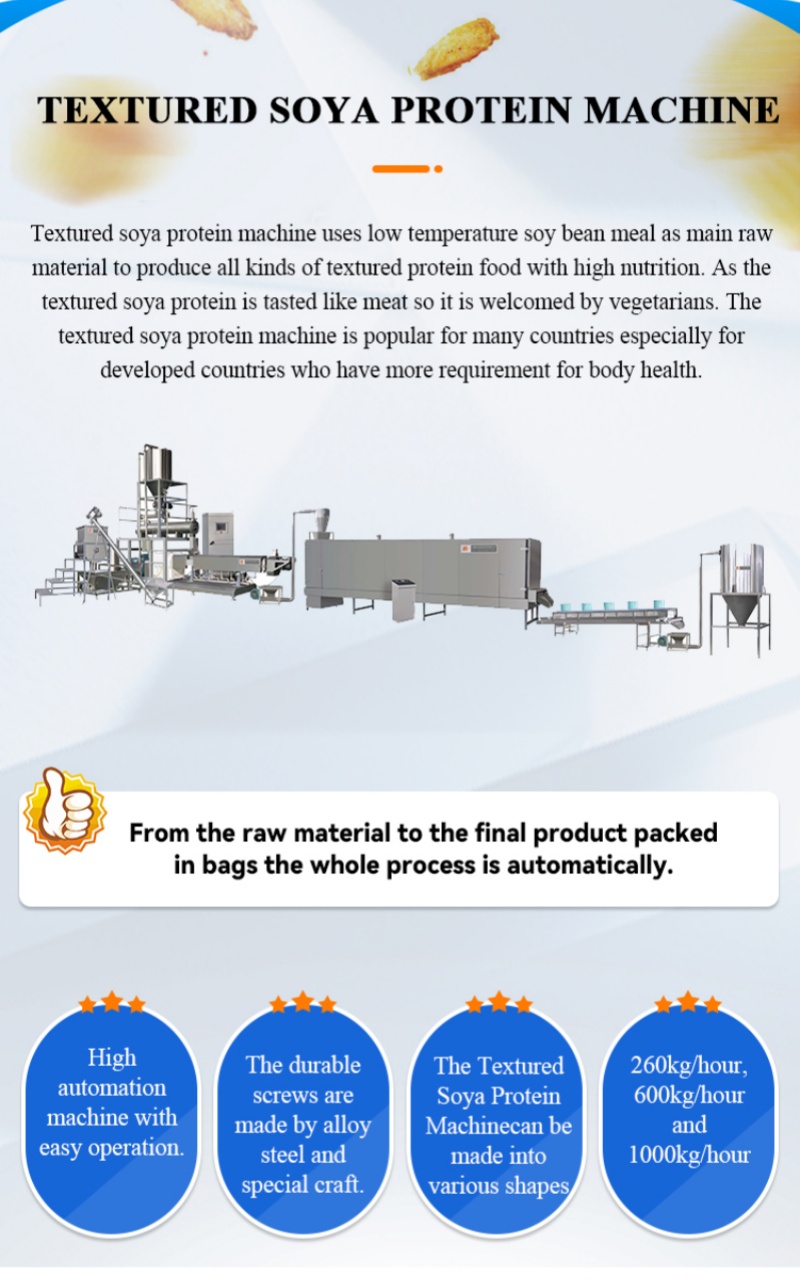

The Soya Minces Production Line is an integrated system that transforms defatted soy flour or soy protein concentrate into versatile, meat-alternative products. The fully automated process ensures high efficiency and consistent quality, making it ideal for large-scale food production.

1. Mixing Raw Material

Soy flour or soy protein concentrate is mixed with wate in a mixing chamber. The mixer mix the raw material evenly and completely.

2. Extruding and Shaping

The mixed raw material is fed into a twin-screw extruder, where it undergoes high temperature and pressure. The extrusion process cooks the material and shape it.

3. Drying the Products

The products are transferred to a multi-layer dryer. Hot air circulation removes excess moisture, reducing the water content for proper shelf stability.

4. Seasoning the Products

The dried products pass through a seasoning drum and spraying system, where liquid or powdered flavors (e.g., savory, spicy, or barbecue) are evenly coated. Optional oil spraying may be applied to enhance texture and taste.

5. Cooling the Products

The seasoned product is conveyed to a cooling coneveyor where ambient or chilled air lowers the temperature. Cooling ensures the product hardens properly and prevents clumping before packaging.

Soya Minces Production Line Sample:

Soya Minces Production Line Parameter:

Model | Install Power | Real Power | Capacity | Dimension |

SLG65-IV | 110KW | 77KW | 250kg/h | 20x 2.0 x 3.0 |

SLG65-V | 135KW | 95KW | 300kg/h | 25x 2.0 x 3.0 |

SLG85 | 210KW | 147KW | 600kg/h | 32x 2.0 x 4.0 |

SLG95 | 300KW | 200KW | 1200kg/h | 40x 2.0 x 5.0 |

Product Features:

The Soya Minces Production Line has some advantages:

*Low product cost and high profit.

*The textured soya protein can be made into various shapes such as ball, pipe and so on.

*The durable screws are made by alloy steel and special craft.

*Visible auto-temperature controlling system with precise temperature viewing.

*High automation machine with easy operation.

Whatsapp:86 18406585795

Ms. Vivian

Related Products

Related News

Submitted successfully

We will contact you as soon as possible